Closed-mold vacuum infusion processing of composites, is recognized as offering reduced volatile emissions, higher fiber content, and improved laminate quality relative to the baseline open mold wet lay-up process. Additional benefits include a low capital investment and an easily manageable learning curve. Accordingly, examples of its use in wind turbine construction abound, from rotor blades to nacelles. Recent advances in infusion specific textiles present an evolutionary step towards further reductions in manufacturing costs while reducing the carbon footprint for wind turbine manufacturers. The advantages these products pose extend beyond consideration of cost and carbon footprint, however, as they offer superior post-fabrication adhesive joining of composite structures.

Process Explanation

Vacuum infusion processing was born from the desire to mate the value proposition of aerospace closed molding to the needs of the commercial manufacturer engaged in open mold processing. In closed mold processing, liquid resin is injected using a pressure gradient. In vacuum infusion processing, negative pressure provides the gradient needed to motivate resin flow.

There are two basic vacuum infusion-processing techniques: surface infusion and inter-laminar infusion. In both practices, a flexible bag or membrane is sealed to a rigid mold to form the “closed” mold. As the closed mold is evacuated by vacuum, the bag collapses against the pre-form, consolidating it against the mold. While this consolidation promotes high fiber content in the final laminate, it does so at the expense of in-plane resin flow. Hence both practices employ a distribution medium designed to facilitate in-plane resin flow, allowing out-of-plane (through thickness) resin infusion to occur. The terms surface infusion and inter-laminar infusion denote the location of the distribution medium relative to the laminae pre-form.

In conventional surface infusion (Figure 1), a removable layer, commonly referred to as a peel-ply, is placed on top of the pre-form before applying the flexible bag and the distribution medium and/or perforated injection tubing is placed on top of the peel-ply. Once the bag is in place, vacuum is applied and resin is drawn through feed-lines into the mold across the distribution medium and through the pre-form. Upon resin cure, the bag is removed, as are the peel-ply and distribution medium, which are subsequently disposed. The peel-ply facilitates removal of the distribution medium while leaving a textured surface on the part for improved secondary bonding. To date, the greatest drawback of surface infusion has been the high waste and cost associated with the application, removal, and disposal of peel-plies and distribution media.

Recently, Polynova Composites participated in a test program to evaluate a commercially available IFR, HIFLUX-90™, as the last ply in surface infusion.

Constructed of high tenacity polyester fiber, the open nature of this textile, shown in Figure 3, assures a high degree of out-of-plane permeability, while its periodically raised or ribbed members (knops) lend a third-dimensional prominence to separate adjacent layers and ensure bi-lateral in-plane resin flow. Engineered with preferential in-plane flow in the weft [90°] direction, the product is well suited for high aspect ratio applications, such as wind blades, where the width presents the shortest infusion path. Further, its good hand and drape eases lay-up of complex parts.

Both composite substrate panels were fabricated at Polynova Composites, of Milford, Massachusetts, USA, by surface infusion using Ashland Aropol 63301-10 INF polyester resin initiated with 2 wt./% Norox CHP. Both resin and room temperature were 23°C, and both composite panels were infused under 91.43 kPa vacuum. Table 1 identifies the substrate laminate schedules.

Study Results

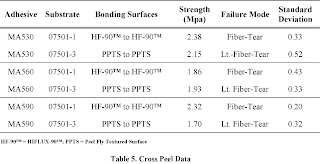

Table 4 contains all lap shear data for this study and Table 5 contains all cross peel data for this study.

Figure 4. Light-Fiber-Tear Failure

For the peel-ply textured surface (07501-3), the mode of failure was Light-Fiber-Tear (Figure 4) which occurs when resin and fibers are pulled free from the surface of one coupon while the adhesive bond-line remains intact on the other coupon. Such failures indicate good adhesion between the adhesive and the substrate, and point to substrate integrity as the limiting factor of obtained strength values.

Conclusion

Social sentiment has undeniably shifted toward an emphasis on reducing industry’s environmental impact. Governmental policies increasingly reflect such interests. Composite materials are widely recognized as key enablers of the green promise. Ultimately, the wind energy industry must adopt composite processing techniques that truly fulfill the green promise by minimizing the carbon footprint created prior to generation of the first watt. Using Infusion Flow Reinforcements™ as the last ply in a surface infusion process enables the elimination of disposable waste streams, while enhancing post-fabrication adhesive joining of the composite structures in the intended application. These attributes pose a winning combination for the environment and manufacturers of wind turbines. While the Plexus® adhesives present a strong choice for adhering the two composite substrates in this study, it is recommended that customers prepare a testing protocol to determine the adhesives’ suitability for their particular applications and processes.

E-BXM 1708 (Vectorply Corporation)

Fiber Type: E-Glass

Architecture: +45°/-45° Double Bias w/chopped strand mat

45°: 304 g/m2

-45°: 304 g/m2

Chopped Mat: 275 g/m2

E-2LTI 3600 (Vectorply Corporation)

Fiber Type: E-Glass

Architecture: 0°/90°/0°/90° Biaxial

0°: 627 g/m2

90°: 608 g/m2

Fiber Type: High Tenacity PET Fiber

Architecture: Proprietary

Areal Weight: 363 g/m2

Knop: Surface projection.

Knop down: projection facing tool surface

Econo Ply E (Airtech International):

Peel ply designed for use in more difficult environments or when a more textured surface is required for secondary bonding.

Resin Flow 75 (Airtech International):

High flow rate disposable surface infusion media

Affiliation:

Patrick Mack is Polynova Composites’ Chief Technologist.

Polynova Composites

229 East Main Street, Ste. 204

Milford, MA 01757 USA

Phone: 508-634-8181

Fax: 508-634-2922

pmack@polynovacomposites.com

http://www.polynovacomposites.com/